Celpoxâ

Aeratsiooniseadmed Reoveepuhastitesse.

Bioreaktorid Celpox

Soojuse efektiivne eraldamine aktiivmudapuhastist

Celpox soojusvaheti

Firma CELPATEKNIK AB ( Rootsi)

Bioreaktor Celpox on uut tüüpi seade aktiivmudasegu õhustamiseks reoveepuhastites. Tänu suurele energiatihedusele ja intensiivsele segunemisele reaktsioonitorus on hapnikusiirdejõudlus väga suur ning aktiivmudaorganismide orgaanilise aine omastamine kiire. Tõhus hapnikusiire bioreaktoris saavutatakse suhteliselt väikese energiakuluga

Bioreaktoreid Celpox saab paigaldada mis tahes kuju ja suurusega aerotanki – nii olemasolevasse kui ka kavandatavasse.

Bioreaktori Celpox jõudlust on hapnikuanduri juhtimisel lihtne reguleerida vastavaks aktiivmuda hapnikutarbele ning see võimaldab väikese reostuskoormusega perioodidel energiat kokku hoida (töötab ainult üks kahest ringluspumbast).

Bioreaktor Celpox on kergesti teenindatav, täielikult mehaaniline seade, mille ainsad liikuvad osad on kaks väikese pöörlemissagedusega aksiaalpumpa. Kõik teenindatavad sõlmed paiknevad pealpool veepinda. Seetõttu ei ole vaja aerotanki bioreaktori hooldamiseks või remontimiseks tühjaks lasta.

Celpoxe valmistatakse mitmes suuruses

Celpoxi saab varustatada lisaseadmetega .

Celpoxi saab varustada soojusvahetiga, et lihtsal ja tõhusal moel kasutada puhastatava reovee soojust.

Celpoxi saab varustada seadmega efektiivseks fosforisadestuskemikaali annustamiseks aerotanki

Celpoxi abil abil saab reovette lahustada mis tahes gaasi.

Celpoxi saab seadistada puhta hapniku lahustamiseks reovette.

Celpox on seade, mida saab kasutada mitmesuguse päritoluga reovee puhastamiseks eri kuju ja suurusega aerotankides.

Celpoxe võib paigaldada ujukitele

Celpoxe saab valmistada , arvestades reoveepuhasti spetsiifikat ja erinõudeid.

Celpox on väga mitmekülgne ja paindlik seade, mis sobib mis tahes ehitusega aktiivmudapuhastisse

Spetsifikatsioon

| Celpox 955 | Celpox 1273 | Celpox 1910 | |

| Reaktsioonitoru läbimõõt mm: | 955 | 1273 | 1910 |

| Vee sügavus H1 m: | 2,5-12 | 2,5-12 | 2,5-12 |

| Seadme kõrgus veepinnast H2 mm: | 1900 | 2100 | 2100 |

| Aerotanki maksimaalne maht ühe Celpoxi kohta (m2) | ~250 (50) | ~750 (150) | ~1200 (280) |

| Mass (H1=4 m) kg: | ~900 | ~1400 | ~2500 |

| Materjalid : | SS 1311-2343 | SS 1311-2343 | SS 1311-2343 |

| Mootorite võimsus N kw : | 4,0 | 7,5 | 15,0 |

| Hapniku siirdejõudlus (SOTR) kgO2/h | 25 | 45 | 90 |

Tootmine ja Müük

AS J.I.T. omab firma Celpateknik AB litsentsi bioreaktorite Celpox tootmiseks ja turustamiseks. Bioreaktorid valmistatakse roostevabast terasest firma Celpateknik AB jooniste järgi. Seadmeid müüakse projektimüügi korras. Kohalevedu, paigaldamine ja häälestamine on bioreaktori hinna sees.

Sobiva bioreaktori valimine

Sobiva(d) bioreaktori(d) valivad ASi J.I.T. või Celpateknik AB spetsialistid arvestades reovee omadusi ning aerotanki suurust ja kuju. AS J.I.T. on valmis pakkuma komplektseid lahendusi reovee bioloogilise puhastamise läbiviimiseks koos selleks vajalike seadmetega.

Bioreaktori rentimine

AS J.I.T. rendib bioreaktorit Celpox aktiivmudapuhastite õhustusjõudluse taastamiseks või suurendamiseks. Keskmine rentimisaeg 0,5–1,5 aastat.

Varuosad

Varustame bioreaktoreid originaalvaruosadega.

Bioreaktorite müügijärgne teenindus

ASi J.I.T. kvalifitseeritud spetsialistid pakuvad järgmisi teenuseid:

- bioreaktorite järelhäälestamine ning aktiivmudapuhastuse tehnoloogiline häälestamine

- bioreaktorite graafikujärgne tehniline hooldamine (lepingu alusel);

- bioreaktorite korrastamine, remontimine ja uuendamine.

Juhendmaterjalid bioreaktorite Celpox kasutajale

|

Celpox 955 teenindusjuhend |  |

Celpox 1273 teenindusjuhend |  |

Tööohutuseeskirjad Celpox seadmete kasutajale |

Celpox soojusvahetussüsteem

Celpox soojusvahetussüsteem on loodud efektiivseks soojusenergia eraldamiseks reoveepuhastusseadmest jaama ruumide kütteks ja sooja vee tootmiseks.

Tööprintsiip

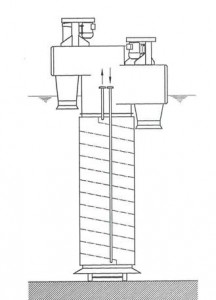

Piirituse või glükooli lahus ( soojusvaheti töölahus) ringleb läbi Celpox bioreaktori reaktortoru ümber asetseva soojusvaheti kesta.

Aktiivmudapuhastis olev soojus kantakse üle ringlevale jahutusvedelikule nii soojusvaheti reaktortoru siseseina, kui välisseina kaudu. Bioreaktori Celpox reaktsioonitorus ja väljaspool toimuvad tugevad turbulentsprotsessid tagavad maksimaalse soojuse ülekande jahutusvedelikule. Salvestatud soojuse transportimine edasiseks kasutamiseks toimub tööstuslikult toodetavate soojuspump seadmetega.

Soojasõlm Vändra

Reoveepuhastusjaamas

Soojasõlm Aseri

Reoveepuhastusjaamas

Soojasõlm Kaarlijärve (Estover Juustutööstus, Tartumaa)

Reoveepuhastusjaamas

Ehitus

Celpox bioreaktori reaktsioonitoru on varustatud topeltkestaga, mille sees kulgeb spiraalne metallvöö, tekitades pika kanali ümber reaktori toru, soojusvaheti vedeliku liikumiseks. Madala temperatuuriga jahutusvedelik suunatakse soojusvahetisse mahuti põhjalähedalt, suundudes edasi spiraalselt ülespoole. Väljutamine toimub reaktortoru ülaosast veepinna lähedalt.

Pikaajalise töö kogemus näitab, et tänu intensiivsele liikumisele kokkupuute tsoonis aktiivmudaga puudub igasugune ülekandepinna kattumine (takistab soojuse ülekannet). Viimane on enamlevinud probleem soojusvahetite kasutamisel tavaaeratsioonisüsteemides.

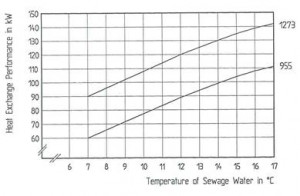

Soojusenergia ülekanne

Soojusenergia tulem jahutusvedeliku voolukiirusel 240 l/min on järgmised:

Vee temperatuur aktiivmudapuhastis 4-7 oC

Celpox 955 60 kW

Celpox 1273 90 kW

Vee temperatuur aktiivmudapuhastis 15 oC

Celpox 955 105 kW

Celpox 1273 135 kW

Paigaldatud Celpox soojusvahetid

| Alfta RVP ( Rootsi) | 1 Celpox 1273 | |

| Munnkfors RVP (Rootsi) | 2 Celpox 955 | |

| Aseri RVP ( Eesti) | 2 Celpox 955 | |

| Vändra RVP ( Eesti) | 1 Celpox 955 | |

| Kaarlijärve RVP (Tartumaa, Eesti) | 1 Celpox 1273 |

|

Soojusvaheti Celpox |