Kontsern ANDRITZ S.A.S.

Seadmed reovee algpuhastuseks ( automaatvõred,treppvõred, trummelsõelurid, tigukonveierid

Seadmed heitvee järelpuhastuseks ( liivafiltrid)

Seadmed reoveesette tihendamiseks ja tahendamiseks ( trummelsõelad, kamber- ja lintfilterpressid, tsentrifuugid)

Seadmed reovesette põletamiseks

Kontsern ANDRITZ projekteerib ja toodab seadmeid nii reovee eeltöötlemiseks, kui järeltöötlemiseks. Reoveesette tihendamiseks ja tahendamiseks ning tahendatud sette kuivatamiseks ja põletamiseks.

|

Kontsern Andritz üldkataloog |

- VÕRED JA SÕELURID

ANDRITZ toodab erinevaid tüüpe võresid ja sõelureid sõltuvalt otstarbest nii tööstuse kui olmereovee eelpuhastuseks

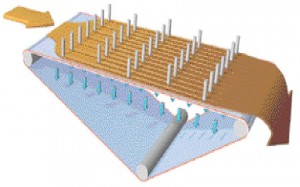

- LIIVAFILTER

ANDRITZ toodab liivafiltreid puhastatud vee järeltöötlemiseks

- DEKANTERTSENTRIFUUGID

ANDRITZ toodab nõrutus- e dekantertsentrifuuge nii sette tihendamiseks kui ka tahendamiseks. Tsentrifuugide juurde kuuluvad abiseadmed settele lisatava polümeeri ettevalmistamiseks ja annustamiseks, pumbad ja tigukonveierid ja tahendatud sette edasitoimetamiseks ning tsentrifuugide ja abiseadmete juhtautomaatika. Tsentrifuuge valmistatakse mitmes suuruses ja komplektsuses. Tsentrifuugimine on täielikult automatiseeritud ning puudub vajadus operaatori pidevaks kohaloluks. Vett on vaja vaid trumli pesemiseks, kui seade seisma jäetakse

Tsentrifuug D1 D2N D2L D2LL D3L D3LL D4L D4LL D5L D5LL D6L D6LL D7L D7LL D10LL D12LL Jõudlusm3/h 1 3 6 8 13 18 28 34 42 65 75 85 100 125 200 280 - LINTFILTERPRESSID

Linttahendi POWERPRESS,

seeria PPG kompaktne , lihtne konstruktsioon

seeria PPE ; PPS keskmise ja pika pressimistsooniga

- SETTETIHENDUSSEADMED